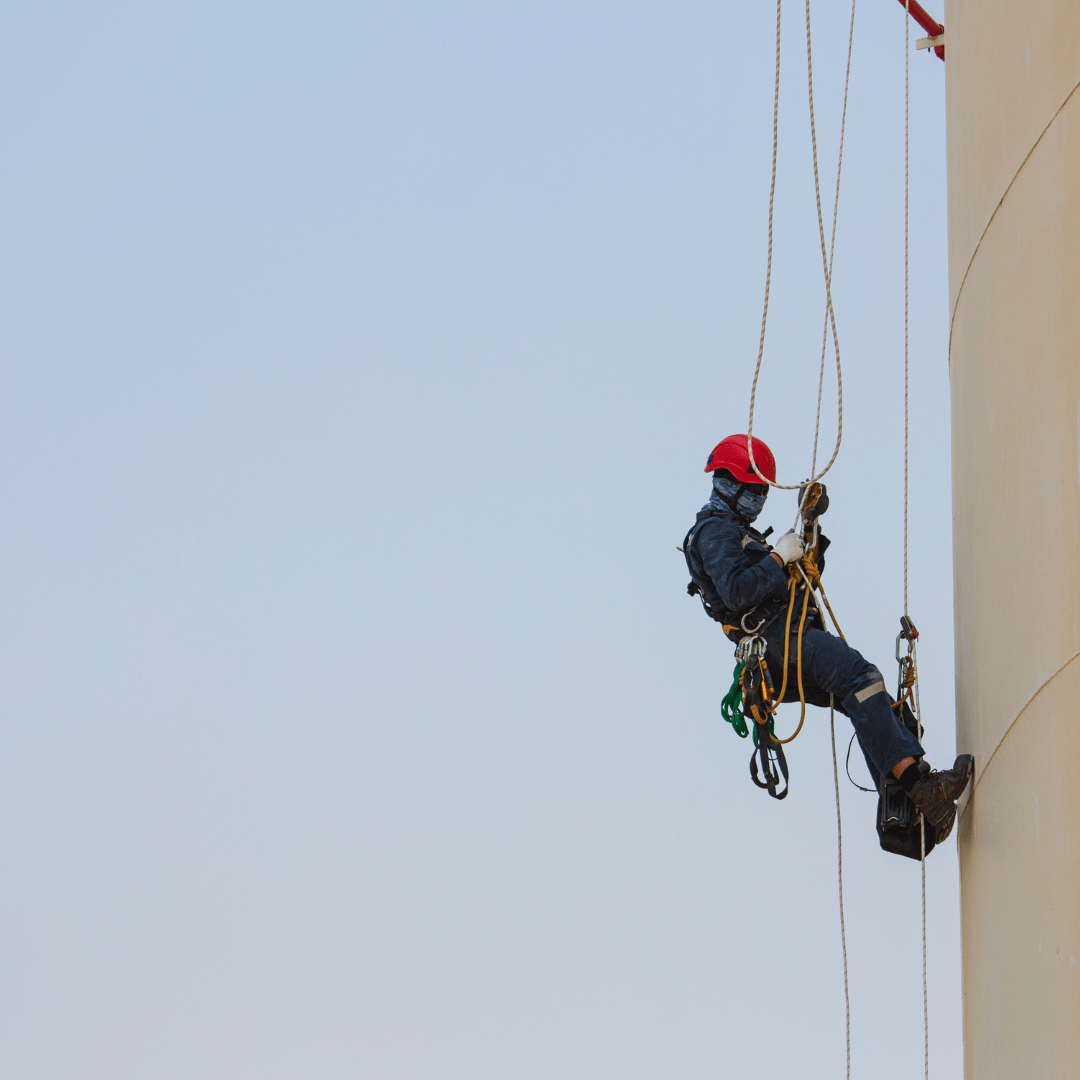

Running a rope access company requires skilled technicians who can work at crazy heights, but there’s a whole world of paperwork, compliance headaches, and operational juggling to consider behind the scenes as well.

Most companies are still doing this part of the job the hard way. Spreadsheets, paper forms, and a prayer that nothing falls through the cracks simply aren’t the best options anymore.

The cost of flying blind

Most rope access companies are running their operations like it’s still 1995. They’ve got quotes scribbled in spreadsheets, job schedules on whiteboards, and safety documents that get copied and pasted from job to job. The result is a chaotic mess where critical information gets lost, deadlines get missed, and compliance becomes a constant source of stress.

Every piece of gear, from ropes to harnesses to carabiners, needs detailed inspection records. This includes tracking serial numbers, purchase dates, and four different types of inspections for potentially thousands of items. Try managing that with a spreadsheet and see how long it takes before something slips through the cracks.

Technician certifications are also important, as we have strict requirements about who can do what, when their certs expire, and how many hours they’ve logged. Miss an expiry date and suddenly you’ve got a non-compliant tech on site, which can shut down your entire operation fast.

The financial impact of these manual processes is significant. Companies lose revenue because they can’t efficiently schedule jobs, miss profit opportunities because they can’t track actual costs against estimates, and face massive penalties when compliance failures come to light. When companies are hit with big fines for workplace safety violations, it’s hard not to think about how that money could have been used to help build your successful businesses.

Where software changes everything

Purpose-built rope access software like JGID makes sense when considering everything mentioned above. Instead of trying to manage everything with disconnected tools, companies get a single platform that handles the entire workflow from quote to payment.

The safety improvements alone are worth the investment. Most incidents happen because of human error. This can be missed hazards or lapses in concentration, but software tackles this head-on by automating the creation of site-specific safety documents. Instead of a project manager copying and pasting from old SWMS documents, the system automatically generates tailored safety documentation based on the actual job requirements. It forces a systematic approach to hazard identification that’s consistent every single time.

The mobile app component is equally crucial. Technicians can complete mandatory pre-start checks digitally, report defects or near-misses instantly, and access all job-specific safety information right from their phones. This creates a real-time feedback loop that helps safety managers spot trends and address issues before they become incidents.

Making compliance manageable

On the compliance side, software transforms what used to be a constant source of anxiety into a “set it and forget it” system. Equipment registers track every piece of gear with automated reminders for inspections and calibrations. Personnel management modules store all certifications with expiry alerts. The system essentially makes your company perpetually audit-ready.

When an inspector shows up, instead of scrambling through filing cabinets and hoping to find the right paperwork, you can instantly generate complete compliance reports. Every equipment inspection, technician certification, and safety document is all there, time-stamped and organised. That level of documentation protects your business from liability if something goes wrong.

The bottom-line impact

The operational efficiency gains are where companies really see the return on investment. Field service management software typically increases job completion rates, which is efficiency that creates direct revenue growth.

The workflow improvements are substantial, too. Quotes convert to jobs with a single click, carrying forward all the detailed information from the initial site visit. Scheduling becomes visual and optimised, with managers able to see technician availability and certifications at a glance. Field teams get job details, safety documents, and client information directly on their mobile devices. And most importantly, invoicing happens immediately after job completion, dramatically improving cash flow.

Job management software you can trust

The companies that thrive will be those that embrace purpose-built solutions like JGID to create seamless, integrated operations. They’ll be the ones who can confidently bid on larger projects, knowing their systems can handle the complexity. They’ll sleep better at night, knowing their compliance is bulletproof. And they’ll see their bottom lines improve as they eliminate waste and capture more revenue per technician.

The technology exists. The ROI is proven. The question isn’t whether rope access software works; it’s whether you can afford to keep operating without it.